Our offer also includes non-standard solutions for PLCs: proprietary applications that allow archiving and processing data available in PLCs. Thanks to them we are able to provide fully developed and very extended diagnostics, which often allows solving problems that are practically impossible to detect by any tools available on the market.

Original, non-standard applications

We offer controller programming services based on existing customer standards as well as our own solutions. Proprietary, open-source prototype systems allow us to generate accurate reports and analysis, save time on technical support and solve out-of-the-box problems

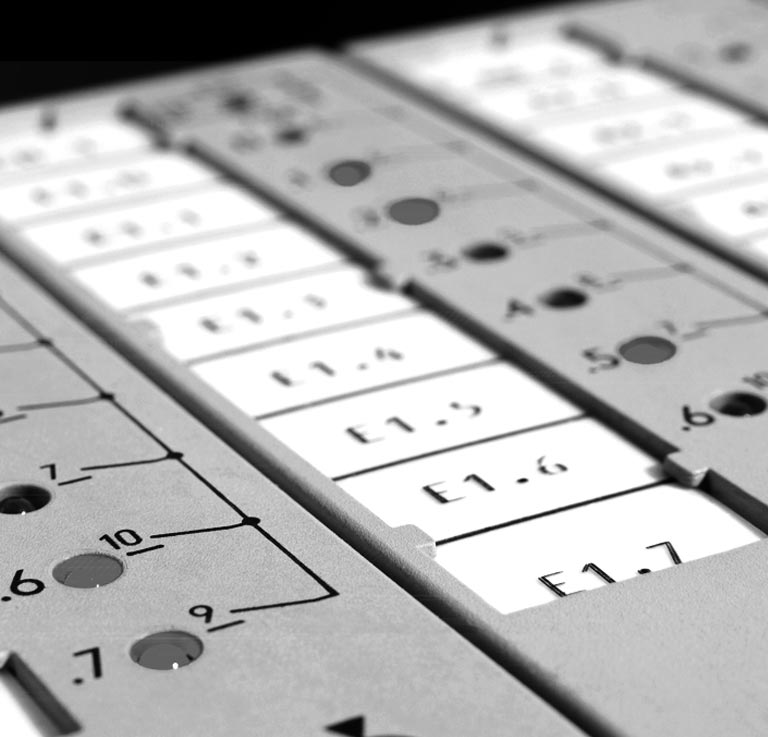

Precise documentation

Every program we create is perfectly documented. We have internal programming standards, and we make sure that our code is clear and easy to analyse, both by our programmers and third-party teams.

Advanced knowledge of standards and languages

Our experienced programmers are familiar with both new and old programming standards and many programming languages to an advanced degree. They have also developed their own internal programming standards.

OUR EXPERIENCE

In control systems programming we mainly use SIEMENS controllers, including SIEMENS FAILSAFE, but we also offer PLC programming of other companies, e.g., Ge Fanuc, Omron. We can boast of many years of experience in programming control systems based on industrial networks such as Profinet, Profibus (DP), Industrial Ethernet and ASI.

We carry out projects using devices from the following manufacturers:

- Step5, Step7, TIA Portal

- GX IEC Developer, GX Works

- RSLogix 500, RSLogix 5000

- Proficy Machine Edition

- EN7

- WinProladder

- CX-One

- U90Ladder, VisiLogic

- WAGO-I/O-PRO (CoDeSys)

- ActWin

At the request of the customer, we can quickly learn the appropriate software and meet the requirements of implementation of the task using machinery and equipment from other manufacturers. Our programmers are happy to take on such challenges and expand their knowledge and acquire new know-how.