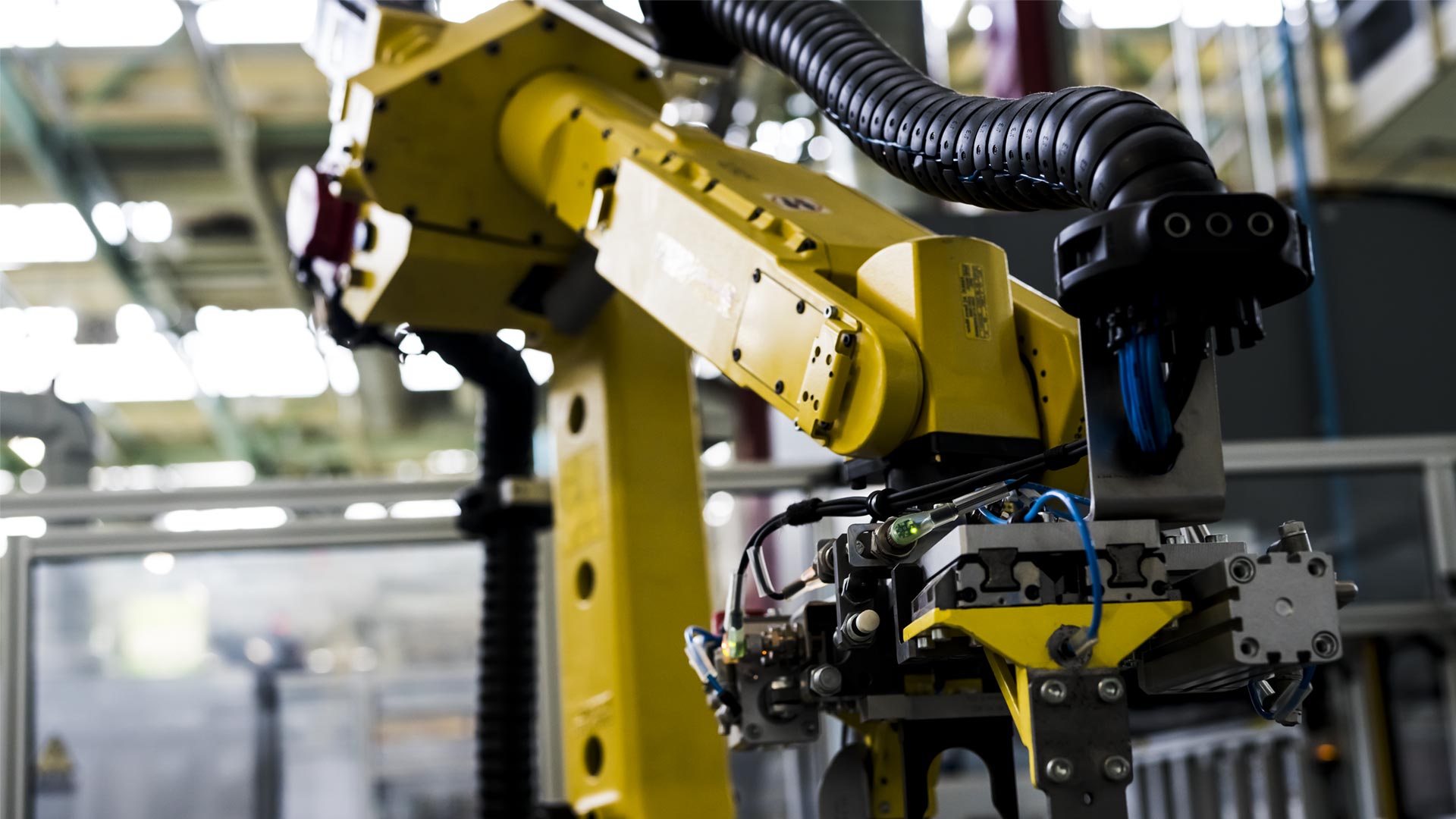

We program industrial robots – ABB, Kuka, Fanuc, EPSON Scara, Kawasaki, Motoman LBR IWA and others. As one of the few only companies in this part of Poland we program the KUKA robot operating with a human.

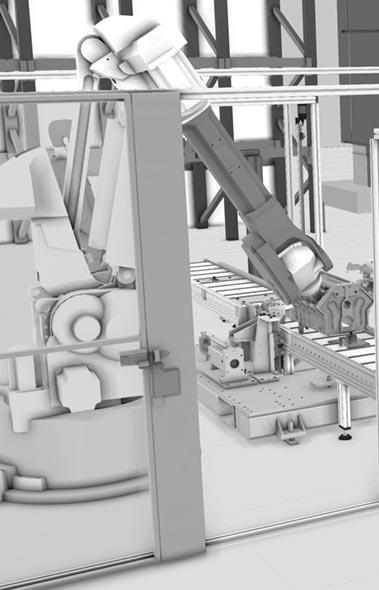

We have years of experience in robot programming and our professionals are not afraid of any challenge, including offline programming.

We provide customized solutions to program each industrial robot to work efficiently and bring tangible benefits to your business.

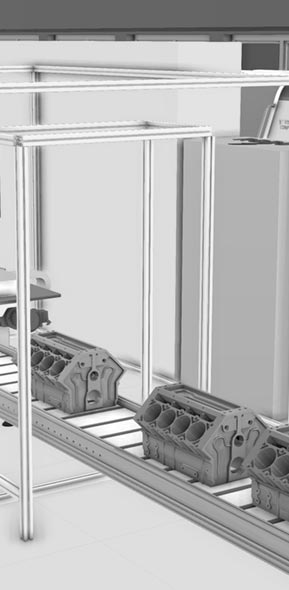

We offer programming of robots taking part in various processes, e.g., cleaning, painting, welding, grease and glue application, production slot handling, palletizing.

THE BENEFITS OF ROBOTISATION IN INDUSTRY

The versatility of using robots in technological processes makes more and more entrepreneurs rely the development of their company on robotization.

Among the many advantages of industrial robotization, the most commonly cited are:

- Replacing human labour with a fully automated industrial robotic structure and eliminating errors due to the human factor.

- Relieving workers by transferring the most difficult or monotonous tasks to robots, as well as those performed in conditions that are harmful to people and in places with limited access.

- Fast, precise, and repeatable robotic task performance.

- Optimize production costs and increase production efficiency.

- Wide possibilities of programming robots and their application in various places and for various processes.